- 13709654005(whatsapp)

- E-mail: ivy@hgprecision.com

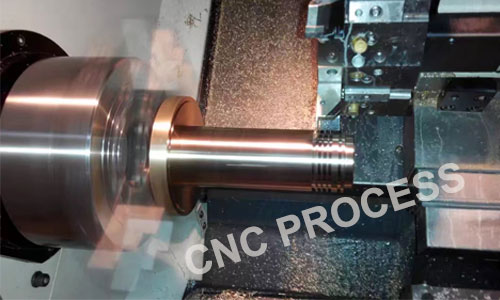

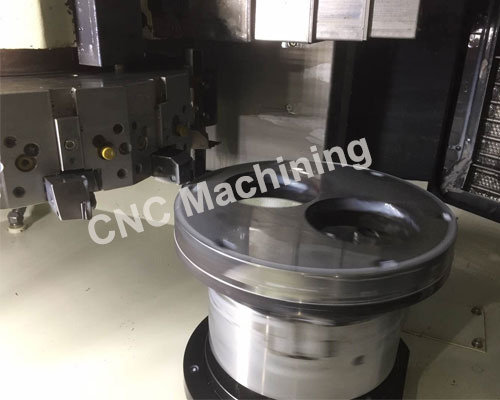

Based on the development of a milling machine automatic processing equipment, the two processing technology is basically the same, the structure is similar.CNC milling machine with cutter base is called machining center.

2. The scope of function of CNC Machining

Good adaptability and flexibility in processing, and can process parts with particularly complex contour shape or difficult to control size.High processing precision, stable and reliable processing quality, numerical control device pulse equivalent is generally 0.001mm, high precision numerical control system can be up to 0.5 m, numerical control processing also avoid operator error.Production automation degree is high, can reduce the labor intensity of the operator.Conducive to production management automation.There are two kinds of CNC in the factory:

CNC is suitable for tungsten steel milling cutter, the surface needs coating, according to the work piece hardness selection.

4. Constraint relationship

1) The depth of the machining hole is proportional to the diameter of the knife.